Product Quality

Quality is no coincidence.

Many capabilities are required from the first discussion until successful implementation. There is quality when customers come back again and again because they appreciate the consistent solution orientation every bit as much as they appreciate the respectful cooperation. The years of experience of our employees creates security and trust.

Product quality

Our hardware has verified availability of > 99.96%. Consequently our product quality includes more than the highest development standards, high-quality materials, and state-of-the-art machines and processing technologies. We also make it our task to permanently optimize all processes and methods along the value creation chain, and to motivate and provide continuing education possibilities for our employees. We can only exceed the high requirements and expectations of our customers through the economic interaction of these four factors.

Quality team

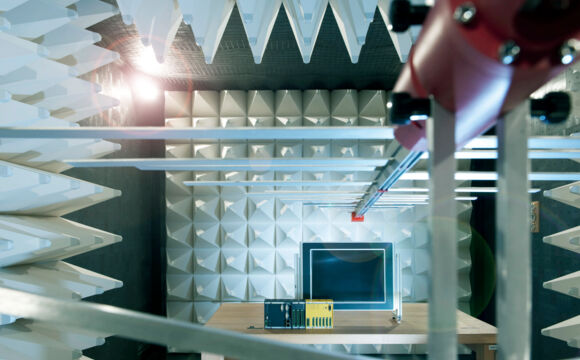

Our quality team monitors the production process, analyses the transmitted machine and process data, and implements appropriate measures to continuously improve our value creation chain. All of our products are subjected to a multi-stage 100% testing process and have passed a 48h run-in test on resistance of environmental influences by means of temperature and humidity fluctuations. Thanks to our 100% test process we are able to guarantee the highest degree of reliability for our customers. Through extensive path and process tracking, consistent traceability of our products, from the supplier to the user, and back (downstream and upstream tracing), is possible at any time. Alternating quality training courses impart the consciousness that every single employee contributes to the high quality standard of our products.

Quality team

- Product development in accordance with StageGate

- HALT (Highly Accelerated Life Test)

- Manufacturer qualification

- Supplier qualification

- Supplier evaluation

- Goods receipt inspection

- Preliminary test of semi-finished goods

- AOI (Automated Optical Inspection)

- SPC (Statistical Process Control)

- Endurance test for finished goods

- Final test for finished goods

- Goods issue inspection (final controller test)

- Internal audits conducted by trained, internal auditors

- Training courses in quality

Certification in accordance with DIN EN ISO 9001 is the foundation of a functioning quality management system for our company. The annual audit by the independent certification institute TÜV-Süd, offers continuous confirmation that the applied quality management system substantially contributes to the continuous improvement and optimization of our products and processes.

Other approvals:

- BV - Bureau Veritas

- LR - Lloyds Register

- DNV/GL - Det Norske Veritas & Germanischer Lloyd

- CE - Declaration of Conformity

- CUL/UL - Underwriters Laboratories

- CCC - China Compulsory Certification

Copies of the certificates are available from our offices, on request.

The environment affects us all

The well-being of every single one of us depends on our environment, and changes to this environment affect us all. It is in our own best interest to protect it.

Bachmann’s highest quality standards, and associated product longevity, form the basis of an environmentally-minded approach to the use of resources. Through the environmental management system, e.g. in accordance with ECOPROFIT (ECOlogical Project for Integrated Environmental Technology) and ISO 14001, our company has committed to comply with environmental standards as well as to the environmentally friendly use of all required resources.

- We focus on product quality and durability, and thus reduce the global use of resources.

- We manufacture high-quality products and minimize our environmental footprint by selecting and supporting suppliers according to quality and environmental criteria.

- We comply with applicable national and international environmental standards and strive to exceed them where possible and necessary.

- We improve our environmental performance by focusing activities on the economical use of resources and energy, including the actions of our employees.

- We strive to integrate the most up-to-date manufacturing techniques into our production processes to minimize environmental impact.

- We ensure that environmental awareness among our employees is part of our corporate culture through continuous education and training.

These are just some of the measures that are an integral part of our active approach to environmental management.

For questions about our environmental management and any reports, please complete the following form:

Questions for our environmental management

Certificates

Excerpt