Processor Modules

Scalable performance and unique robustness.

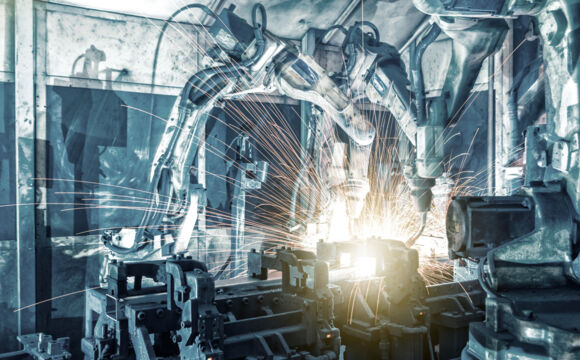

Processor modules form the core intelligence of an automation system.

They collect sensor data, process control functions and closed-loop controls in microsecond cycles, and issue precise commands to actuators. The functions can be implemented in the traditional procedural manner, derived from model-based simulations, or generated automatically with generative AI. Sufficient performance reserves are crucial – for example, to handle parallel motion control, image processing, state data acquisition, and advanced diagnostics.

In addition, processor modules connect real-time processing with IT and OT systems: via real-time Ethernet to the field level and other control nodes, as well as upstream to the control room, MES/ERP systems, or the cloud. Cryptographic methods, hardened system environments, resilient software design, and regular penetration tests are indispensable for cybersecurity.

The non-negotiable basic requirement: reliable 24/7/365 operation.

This starts with the system design – using durable, robust components, generous design reserves, and thorough testing during type approval and series production. These measures ensure that the automation system remains safe and autonomously operational at all times, even under harsh environmental conditions and electromagnetic interference.

Processor modules

What sets them apart:

- Scalable performance up to 1.9 GHz multicore

- Generous RAM up to 8 GB

- 2 to 4 real-time-capable Gigabit Ethernet interfaces

- EtherCAT master and PROFINET controller 1) without additional modules

1) in preparation - Onboard flash and microSD as removable media

- Secure boot with hardware root of trust

- Role-based access control (RBAC)

- Fine-grained permissions system for user applications

- Real-time Linux, process isolation

- Hardware watchdog, RTC, non-volatile memory

- Ultra-fast expansion slot

- –30 to 70 °C, fanless

- 4 g vibration, 20 g continuous shock