Deck Equipment: What Equipment is Needed?

An effective power management system keeps the mission equipment operational for as long as possible.

December 2025

In the previous article, we looked at how C-Systems is rethinking the propulsion system of the cable repair ship currently being built by Dutch shipbuilders Neptune Marine. Now let’s take a closer look at what is considered by many as being even more important than propulsion: the ship’s mission equipment. These are the tools for the task at hand. For a tugboat, the focus is on towing winches and capstans. For crew transfer vessels, an effective and safe motion-compensated ‘walk-to-work’ gangways is a must. For this particular cable repair ship, the primary mission equipment consists of the cable carousel and tensioner which (besides the storage of subsea cable) have the main functions of deploying and/or recovering cable to and from the seabed.

As you can imagine, the cable carousel requires a substantial power supply to perform its job. Once again, this is where C-Systems is bringing its innovative way of thinking to the project.

If the mission equipment on a cable repair vessel fails, the cable may be damaged. This damage can be caused by excessive tension or a kink. Locating and repairing or replacing the damaged cable can significantly impact the project’s turnaround time. In all cases, but especially when unexpected events occur, the safety of the people on board is paramount.

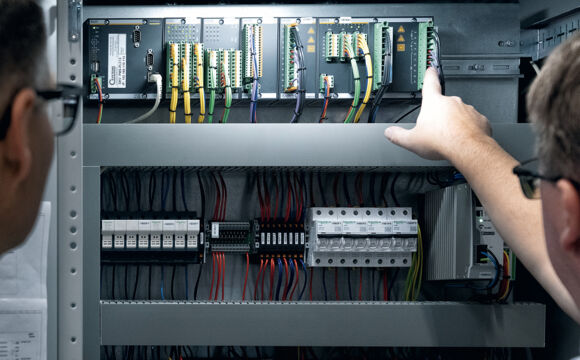

Jeroen describes C-Systems’ design philosophy as “always trying to do our best in keeping the mission equipment operational for as long as possible”. Installing a closed bus electrical system rather than the typical open bus method is an important part of this way of working. As such, an accurate knowledge of onboard power demands is critical. “The closed bus system allows enables a leaner power system made possible by knowing exactly what power is required for different operations,” adds Jeroen.

Communication with the customer is key. “We are talking with the customer; they are the ones who will be using the mission equipment. And we are having conversations with the manufacturer of the mission equipment in order to add an interface between their equipment and our equipment. This way, we will know what power requirements we have to expect.”

This interface will allow C-Systems to reserve power across all consumers. More importantly, however, these power management decisions will be based on priorities set by the vessel master. “The vessel master can decide which onboard consumer has the highest priority at any given moment,” explains Jeroen. “It could be the thrusters or carousel – or maybe another system – the master selects who gets the power first. This allows us to better manage the requested power in the system. We can create a number of operational modes that are set from the priorities of the customer’s operational profile.”

During free cable-laying operations, for instance, the carousel will take priority over the ship’s propulsion system. “When you are laying cable over the seabed, the vessel’s speed is actually dictated by how fast you are paying out the cable. The carousel speed – or rather the cable tension – determines the speed of the ship through the water. In other operations, such as normal dynamic positioning mode, the thrusters take the priority. This level of integration allows the customer to offer the vessel for a wide range of projects.”