Industry 4.0 –

The Peak of Industrial Automation

Pioneering digitalization for mechanical and plant engineering.

Industry 4.0 is diverse and complex - we have the perfect solutions.

Whether machine or system; automation, monitoring or control - we are ready for the challenge.

Challenge Accepted

For over 50 years, we have delivered customized solutions for specific market and customer requirements. Today and for the future.

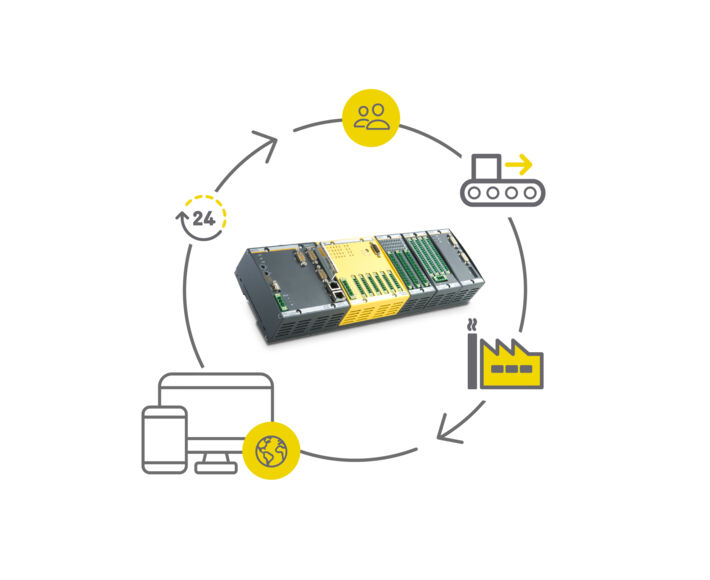

Big Data and our Demands for the Hardware of the Future

We move with the times and with the latest technological developments. Industry 4.0 is not an individual function, but a fundamental architecture that we have been pursuing for years. Fleet monitoring of plants and machines is the logical continuation of this trend and our contribution to product realization.

- Robustness + long-term availability > 99.96 %

- Reliability + access protection

- Flexibility + compatibility

- Automation technology openness + usability

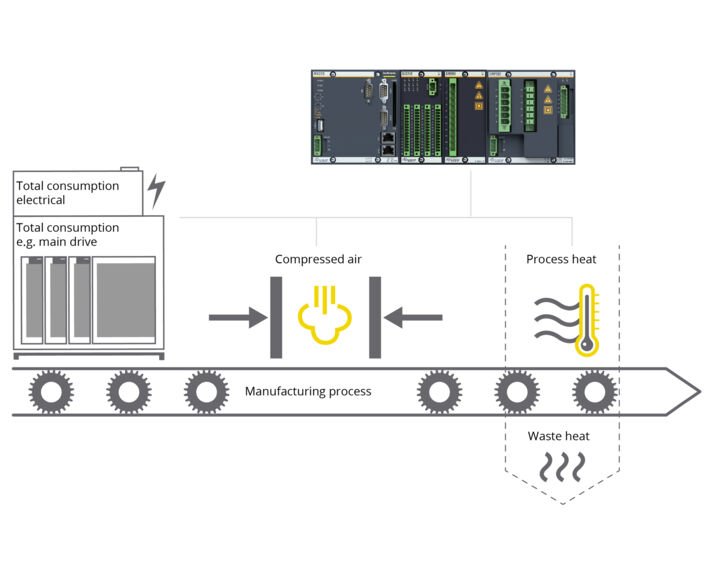

The Bachmann System

We see the big picture and are always thinking one step ahead. Our innovative solutions ensure efficient plant engineering. Intelligent automation of modern industrial facilities looks exactly like this.

Take a short look through our system world: | ||

| 1. Controller System | 2. Web Visualization | 3. Independent with atvise scada |

| 4. Ready-to-use Security | 5. Integrated Safety Solution | 6. All-in-one Engineering-Tool |

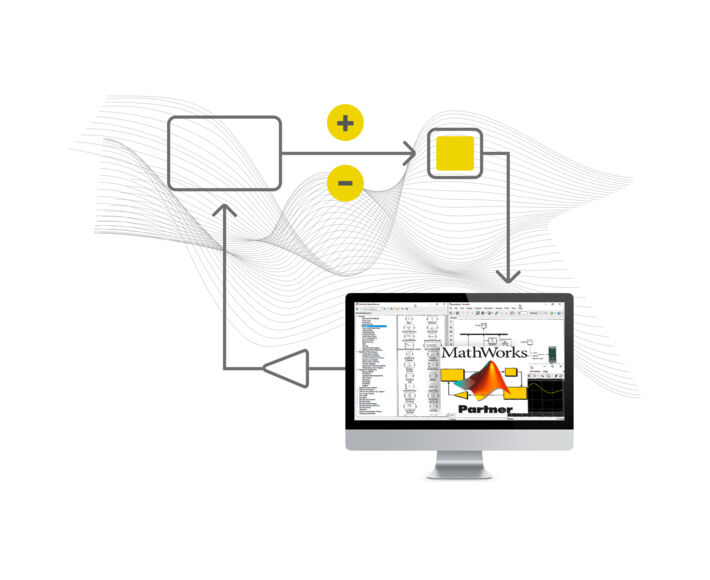

| 7. Individual Drive Solutions | 8. M1 ServiceCenter | 9. M-Target for Simulink |

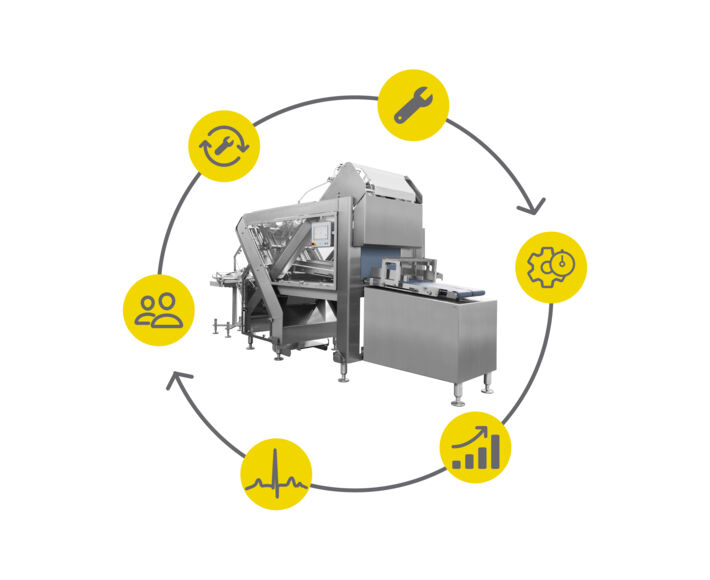

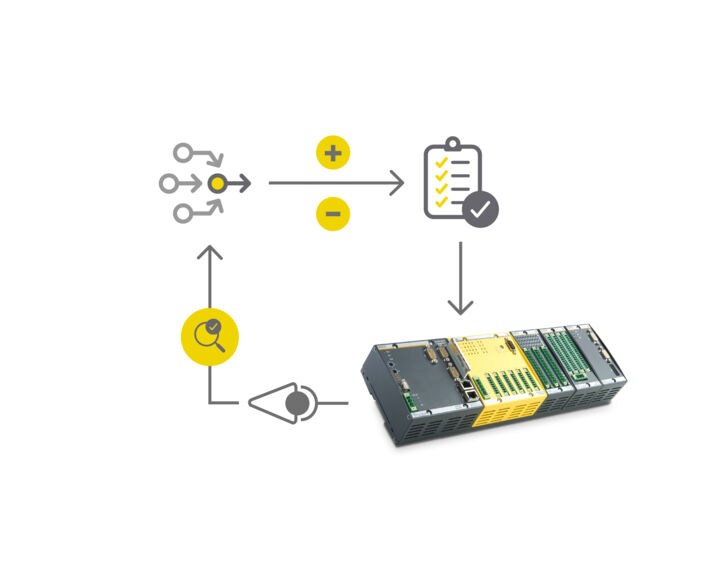

| 10. Adaptive Temperature Controller (ATeC) | 11. Repair and Maintenance | 12. Scope 3 Data Recorder and Watch List |

| 13. Controller-Integrated Power Measurement | ||

Companies who trust Bachmann

Excerpt

Applications

Here you'll find a small selection of our application reports.

Click here for more.