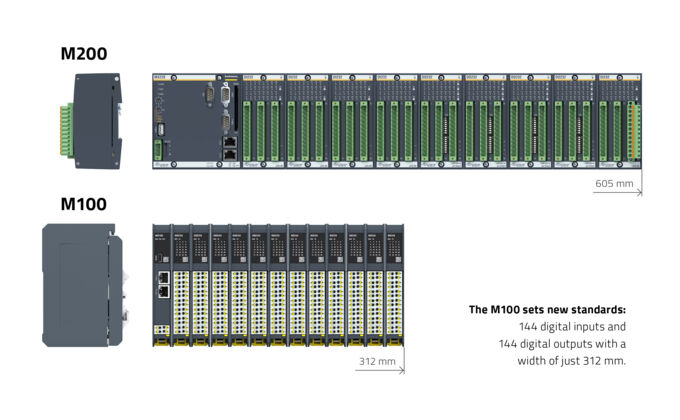

M100 Series - Slim and Strong

December 2022

Bringing decentralized periphery into new dimensions: With the launch of the M100, Bachmann delivers an I/O system which, thanks to its uncompromising robustness, fits perfectly into the Bachmann portfolio. But not only that – the M100’s compact dimensions also open up completely new possibilities for machine and plant builders.

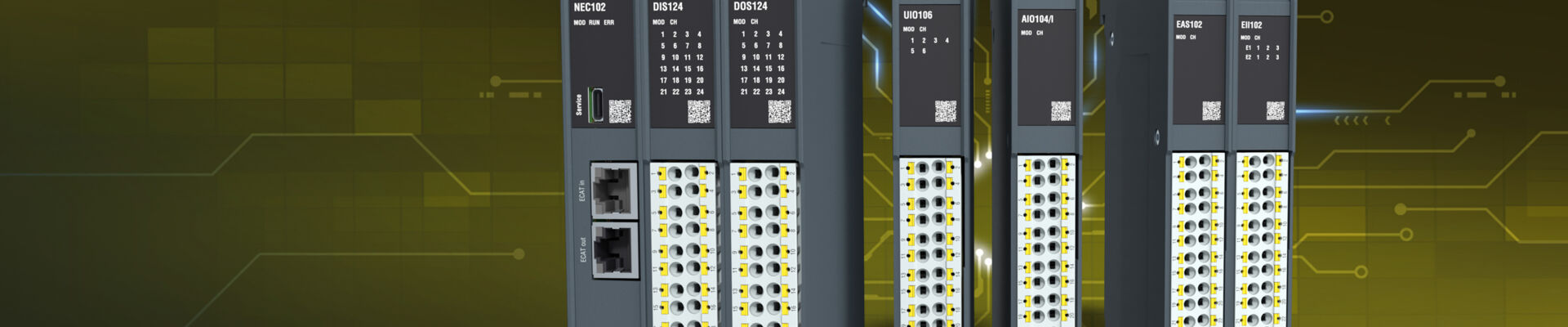

In a world where automation has always required a choice between durability and compactness, the M100 from Bachmann provides the answer: 24 digital or 12 analog inputs/outputs that require a module width of just 24 millimeters. With a focus on maximum availability and stability, the system makes no compromises despite its small size. Each module, packaged in an EMC-proof metal housing, withstands shock, vibration, extreme temperatures and condensation – everything you have come to expect from Bachmann automation systems over the previous decades. Never before seen, the M100’s high density of functions is possible due to state-of-the-art technology and a sophisticated thermal design. The housings do not even require ventilation slots, eliminating the risk of production- or maintenance-related dirt or particles contaminating the system.

Built to withstand the elements

Modular machine concepts significantly reduce the cost of variants. The decentralized positioning of I/O stations also reduces wiring effort, and therefore costs. With the M100 I/O system, up to 744 digital or 372 analog channels per station can be positioned cost-effectively in the smallest possible space. For the first release, Bachmann has utilized EtherCAT as a standardized, real-time capable fieldbus. Subsequent releases will also enable the use of other communication standards to connect with the M100 I/O system. Thanks to the M100’s IP40-compliant design and mounting concept, stations can be mounted directly on or in the machine, either on a DIN rail or with screw fixings. Individual modules are also screwed into place, remaining stable even under considerable vibration or impact loads.

State-of-the-art technology

Bachmann adopted the most up-to-date approaches when designing the hardware platform: System architectures, processors, logic, and signal interfaces are based on the newest technologies and provide a backbone for minimal power loss, ultra-fast data transmission and next-generation IT security. Secure Boot initialization prevents any compromise to fieldbus hardware, and enables the secure integration of remote I/O stations into the automation network.

The internal, active module bus is designed for a data throughput of 50 Mbit/s per module, making it a long-term solution for data-intensive applications. With big data in mind, the M100 provides machine builders with a solid foundation for future applications, such as predictive maintenance.

Best-laid signals

Signal connectivity has also undergone a major redevelopment: cables connect directly to the module at push-in, spring-loaded terminals, and the fully-removable connector allows the control cabinet to be prewired without electronics. All contact elements are generously dimensioned for UL-compliant wiring and are locked to prevent vibration. A separate test connection also enables convenient signal measurement. The I/O modules are available for multi-conductor connection technology (2-, 3- and 4-wire).

Next-level engineering

Project planning takes place in the familiar Solution-Center – but with completely updated usability: "When it came to the M100 I/O system’s user configuration, we decided to start from scratch and came up with a completely new approach," says Daniel Pfeifer, Technology Director at Bachmann electronic.

It goes without saying that M100 units are fully compliant with all relevant standards. This makes them particularly suited for demanding applications in challenging environments, such as on maritime vessels. M100 delivers robustness and high availability, everything you expect from Bachmann. And with the slimmest dimensions to date.