Millimeter meets Kiloton

Precise synchronization

Mammoet jack solutions lift extremely heavy structures high into the air. The multiple hydraulic cylinders required must lift thousands of tons with millimeter precision and perfect synchronization to ensure safety on site. Based on the M200 control system from Bachmann, system integrator Hycom B.V. from Enschede (former Hydrodynamics B.V. Netherlands) developed a hydraulic system that matches these requirements perfectly.

Hycom specializes in the development and production of advanced hydraulic systems. The company was founded in 1974 and, in 2013, was fully integrated into the Hydac International Group. Hycom customers include renowned international shipyards, dredging companies and offshore plant manufacturers. One of these customers is Mammoet, with its Mega Jack 5200 jack-up system.

This revolutionary solution enables extremely large and heavy superstructures to be lifted efficiently and safely. It increases safety for Mammoet's customers, as much of the work can be carried out in advance at ground level. It also reduces construction costs and speeds up assembly. Theoretically, the turnkey system has an unrestricted lifting capacity thanks to an unlimited number of powerful jack towers. The Mega Jack 5200 has been used to lift structures weighing over 40,000 tons.

Undesirable complexity

Hycom was assigned to optimize the existing hydraulic control system of the Mammoet lifting system. “The previous system had one major disadvantage: A jack tower consisting of four cylinders was realized by two combined dual-axis controllers, each with its own control system, interfaces and software solution. If several jack towers were required for a project, system complexity increased enormously. It was therefore very difficult for Mammoet to determine exactly where the problem was when something was not working as it should,” explains Roy Beverdam, Hycom General Manager.

Precise synchronization

Hycom developed a new control concept in less than three months. Their specialists had already had a positive experience with Bachmann during other projects, which is why they selected Bachmann’s real-time systems for precise control and synchronization of the jack towers in this safety-critical application. Each tower now has its own Bachmann automation system to precisely control the cylinders and all associated components, as well as the diesel unit. In turn, every tower controller is networked via a central main controller. “This makes it easy to move 40 cylinders or more, with a maximum tolerance of half a millimeter,” says Roy Beverdam, impressed by the precision.

An MX207 processor with ISI222 positioning module, a PVA208 proportional valve amplifier, an AIO216 universal analog input/output module and a DIO232 digital input/output module are used for each of the subcontrols. Communication takes place via CAN bus using the CANopen master module CM202.

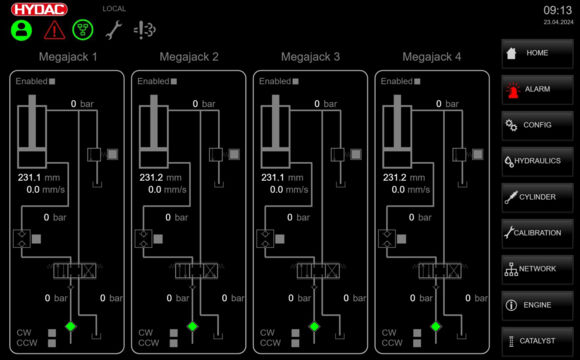

Everything in sight

The system is designed for remote operation via a central Human Machine Interface. The tower controls are visualized directly on the M200 controller with the SCADA web interface WebMI pro. If required, this gives Mammoet in-depth insights into the details of each individual cylinder – right down to the exact status of the hydraulic valves, which also play a central role in safe lifting and precise control. “Helpfully, we can use flow diagrams to see exactly which parts of our systems are currently active and which are inactive,” says Roy Beverdam.

Scope 3 has also proven to be extremely valuable, adds Roel Ymker, Application Engineer at Hycom: “The Scope function is really great. It helps a lot with commissioning and troubleshooting. We can examine every channel in detail and analyze the results in MATLAB Simulink®.”

Intelligent software

Normally, special stand-alone axis controllers are required to reliably control all possible load scenarios, says Roel Ymker: "However, these involve a high process load. Thanks to Bachmann, we could use our own software to solve all calculations directly on the controller. This allowed us to create a complete, integrated solution."

Thanks to the flexibility of the application program implementation by Hycom, the integration of various diesel units is simple and straightforward. An important software detail is the load

control: "To keep the structure stable, you have to slowly increase the forces before the load is lifted for the first time. Depending on the position, the load is shimmed to achieve a level lift lifting," explains Roel Ymker, adding: "Another challenge was the dynamics. Initially, it was necessary to adjust the control parameters after every few meters lifted, as the dynamics of the system change with its height." An electronic pressure compensator was therefore installed so that the system could be operated with the same parameters, regardless of height.

And the journey continues

Hycom is already working on their next projects with Bachmann, such as the construction of the Fehmarnbelt tunnel between Denmark and Germany – the longest underwater tunnel in the world, due to be completed in 2029. The specialists are responsible for the exact positioning of 89 tunnel elements on the seabed. This is where millimeters meet kilometers, as the required positioning accuracy is just 15 mm, with a tunnel length of 18 km. Communication takes place via the bluecom open real-time transmission protocol.