When the flood of data understands itself...

AI and IoT open new perspectives for visualization

Visualization is on the verge of a profound change. It is a transformation that is indeed necessary to meet the requirements imposed by Industry 4.0 and 5.0. Human-machine interfaces (HMIs) and SCADA systems are evolving such that they can efficiently analyze huge amounts of data, present it intelligibly and support decision-making processes for industries. New technologies such as AI, IoT, and immersive forms of presentation – in other words, virtual reality – open the door to totally new possibilities for monitoring and optimizing industrial processes.

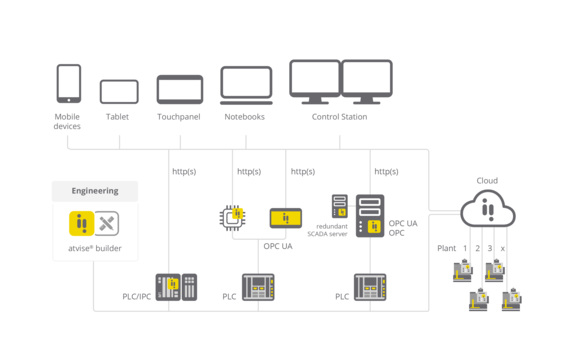

Industry 4.0 brings an unprecedented flood of data into the production world. HMI and SCADA benefit from the networking offered by the industrial Internet of Things (IIoT). IIoT paves the way for new data integration and monitoring opportunities. Rather than replacing obsolete systems, modern approaches integrate new technologies, to improve performance and render complex processes more accessible. For example, open IoT (Internet of Things) technologies such as Raspberry Pi or Node-RED enable cost-efficient and adaptable visualization solutions that integrate seamlessly into existing architectures.

Industry 5.0: Human-centric visualization

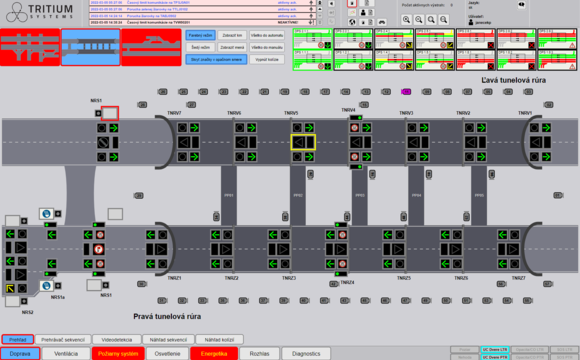

With the vision of Industry 5.0 the focus is shifting even more towards the human being. The increasing complexity of industrial control systems and the growing flood of data require new approaches both for presenting this information and for using this information. An innovative framework for automated HMI designs is the key that enables user-defined visualizations in real time. These are visualizations that can be adapted to the specific requirements of the user. This level of visualization adaptability increases situational awareness and significantly improves decision-making processes. Of particular importance in this regard is presentation of data in versatile formats – from interactive 3D visualizations, dynamic dashboards, and on to 3D visualizations that make complex processes more tangible.

GenAI – trailblazer for visualization

Today generative AI (GenAI) offers totally new perspectives for visualization. For example, given GenAI's capability to recognize data patterns and automatically generate visual presentations, data analysis, interactive maps, and user-friendly dashboards can be designed much more efficiently. Integrating GenAI into existing systems holds the potential of lifting HMI and SCADA to a new level. Through GenAI prefabricated visualization formats be used, however, dynamic and user-centric adaptations can also be implemented. This requires an interactive utilization where users can autonomously analyze data and generate personalized presentations.

Cyber-physical production systems: insights and interoperability

Cyber-physical production systems (CPPS), in other words a composite of IT components and software components with mechanical parts and electronic parts, that communicate by means of a data infrastructure such as the internet, extend the possibilities of traditional automation solutions, because they use standardized protocols like OPC UA, to ensure seamless communication between machines and visualization systems. In this respect, a particular challenge is to design the systems such that even users without in-depth technical skills can benefit from the new technology. Thanks to flexible data structures, information from different sources can be bundled and processed in a meaningful way.

The future of visualization: flexibility, data centralization, and scalability

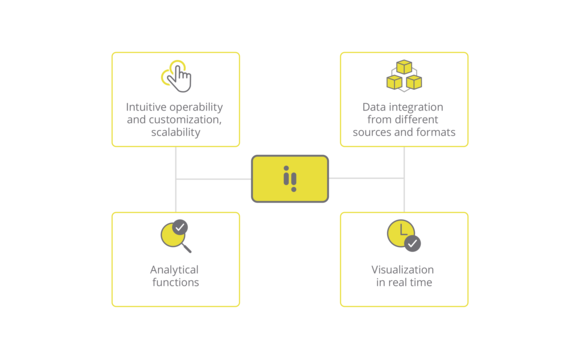

The future lies in flexible and scalable visualization solutions that dynamically adapt to the users' needs. Interactive analysis tools and configurable visualization components offer plant operators the possibility of combining information from various subsystems; and thus make well-founded decisions in real time. In this respect, data-centric approaches are becoming increasingly relevant: Modern systems make it possible to integrate vast amounts of data from a wide variety of sources and to transform this data into usable information. In the future, visual tools will even be more closely fused with analytical modules, such that they not only present data, but that they also optimize its contextual significance.

Real-time scalability is another focus area: Systems must be able to keep pace with growing quantities of data and at the same time provide intuitive operation possibilities to the users. In this regard, new technologies such as interactive 3D visualizations and virtual reality (VR) can help in presenting complex processes with even greater clarity and providing new possibilities of interaction.

Specialists and know-how-carriers play a special role here. With their expertise, added-value information can be selectively extracted from the enormous floods of data. Such specialists work with both classic and new visualization technologies, and they do so not only to solve problems but also to promote pro-active decisions. Their input is crucial. It ensures that the data presented is accurate, relevant and at the same time offers new insights into the operational processes.

The role played by engineering is also an important aspect in this context. Note that specialists with expertise in the respective industrial process will still be needed for in-depth analysis and interpretation of data. However, in recent years the creation of visualizations has been significantly facilitated. Modern low-code and no-code platforms make it possible to generate high-performance, user-friendly visualizations without extensive programming skills. This means that engineers and specialists can directly access visual presentations and flexibly adapt them on their own, without the involvement of specially trained software developers. Not only does this accelerate implementation, but it also increases the adaptive capability of visualization systems to specific requirements.

Requirements imposed on modern visualization systems

To meet the requirements imposed by Industry 4.0 and 5.0, modern visualization solutions must offer several core aspects:

Visualizations should be intuitively operable, and they should be tailored to the specific needs of the users. User-defined adaptations and the possibility of carrying out ad hoc data analyses are key aspects.

Systems must be able to integrate data from the most disparate sources and formats, and to make this data accessible in a uniform platform. Given the exponential increase in data volumes, visualization tools must be flexibly scalable to meet the needs of both small and large applications.

Conclusions

HMI and SCADA are key technologies of the present and they are also trailblazers for the industry of tomorrow. By combining traditional strengths with innovative approaches like GenAI, open technologies and human-centric designs, HMI and SCADA establish the foundation for a networked, efficient, and user-friendly industrial future. The visualization of the future will be characterized by a close connection between data, presentation forms, and ease of use. The journey into this future has begun – and it promises to fundamentally change the way we understand production and processes.