Condition monitoring on board

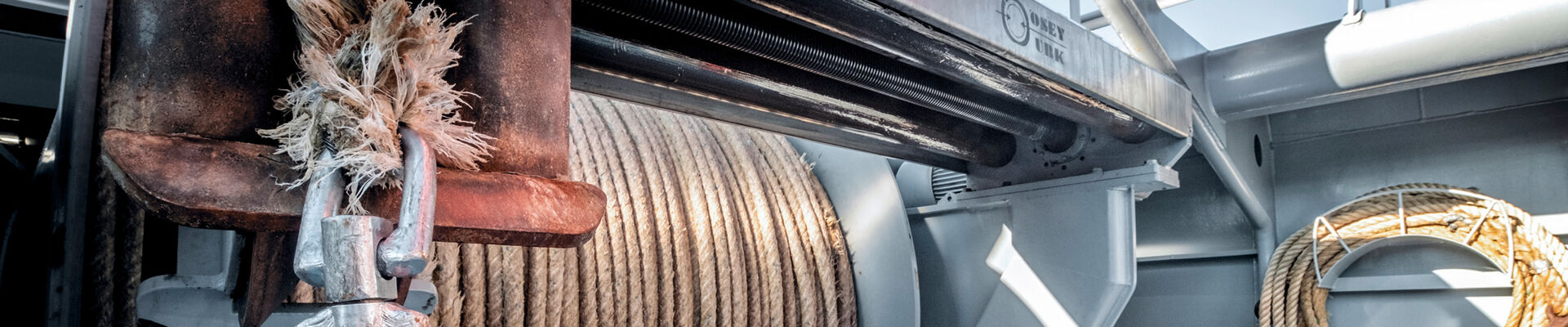

Bachmann technology detects hidden weak points in cable winches.

Dromec, headquartered in Rhenen, Netherlands, specializes in high-performance winch development. A fishing company customer was struggling with defective gearboxes in its electric winches. The cause of the issue was unknown. Dromec sought advice from the condition monitoring experts at Bachmann Monitoring.

If a winch gearbox malfunctions while a vessel is at sea, it creates a significant problem for the fishing company. "Fishers sometimes travel for over half a day to reach their fishing grounds. If a defect occurs, they have to travel all the way back to repair the winch, which means losing a full day's catch," explains Geerart de Vree, Technical Director at Dromec.

The company has already experienced four defective gearboxes. To determine the cause behind the failure, Dromec temporarily installed a Bachmann M200 controller, three vibration sensors on each of the two gearboxes, and two sensors on the ship's two 200 kW electric motors. The experts at Bachmann Monitoring thoroughly analyzed and interpreted the recorded data. "The condition monitoring system provided us with a comprehensive and precise overview of the individual components. For instance, we identified a rusted bearing on the electric motor's fan due to increasing friction, which had created a new frequency in the spectrum. This meant we could replace the bearing before it failed completely," says Geerart de Vree.

However, the issue remained unresolved. Gearboxes continued to malfunction. “Interestingly, the phenomenon did not occur as the catch was brought in - when torque was high. It occurred as nets were deployed, when load was minimal and the winches were rapidly unwinding the lines. That was a surprise." Dromec subsequently modified the control system to trigger a warning signal for the captain when the ship's speed exceeded a set threshold. "Flyshoot fishing takes about 90 minutes. If maximum speed is reduced by 10%, fishers only lose around 30 seconds when setting the nets – less than 5 minutes over a whole day," calculates Geerart de Vree, adding: "Since we made this adjustment, the gearboxes have been operating perfectly. We are happy to see everything running smoothly again."