Efficiency on a new wave

Bachmann technology controls the complex energy management system of the Windkeeper fleet.

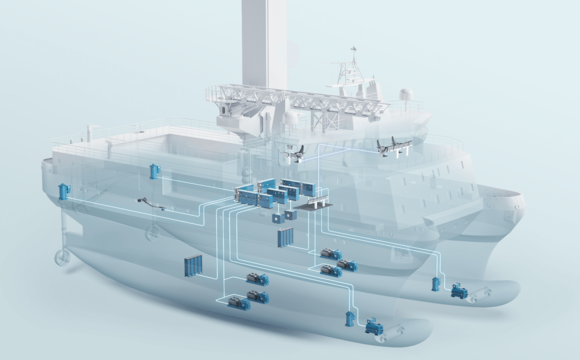

Two particularly innovative service vessels for the offshore sector, the Wind King and Wind Queen, will enter service in 2026. The Windkeeper series, with its hybrid propulsion concept, was developed for maximum energy efficiency. It can be powered directly from the offshore platform, enabling it to remain at sea for months at a time. The entire on-board energy management system is monitored and controlled by Bachmann M200 automation systems.

The offshore wind industry is faced with the task of making service operations at sea more efficient and safer. What is needed are vessels that can precisely maintain their course and position even under difficult conditions - and thus reliably transport personnel and materials to the turbines. With the Windkeeper, the Norwegian shipowner GC Rieber Shipping has developed a Service Operation Vessel (SOV) that is designed for precisely this purpose: for the energy-efficient, safe and economical operation of offshore wind farms.

Secure transfer

The ship's twin hull concept - a so-called Small Waterplane Area Twin Hull (SWATH) design - significantly reduces wave reaction and ensures exceptional stability and operability even in rough seas. In combination with the dynamic positioning system (DP), the Windkeeper remains safely in position even in wave heights of up to four meters. This enables safe and comfortable transfer of passengers via the gangway, which can be extended up to 30 meters - even under the most demanding conditions.

Redundancy is the top priority

However, the extraordinary design of Windkeeper places highest demands on the energy architecture. In order to implement the complex energy system topology with its numerous redundancy zones, GC Rieber Shipping commissioned Bergen-based Norwegian Electric Systems (NES), one of the leading system integrators for customized AC/DC energy networks and propulsion systems in the maritime sector.

Despite the high complexity of the energy system, the size, weight and arrangement of the numerous switching units could be reduced and optimized compared to conventional systems.

Intelligent power distribution

At the heart of the energy infrastructure are the „Quadro Master” DC switchboards and the „Odin's Eye” DC grid system from NES. „As the power center, they ensure that energy flows reliably to every part of the ship, from the propulsion system to the critical devices on board,“ explains the NES engineer. At the heart of this is a fully doubled, ring-based DC power supply system that includes several redundancy groups and batteries. „In addition to the option of fully electric operation, the energy storage systems provide reliable power reserves, balance loads through peak shaving and enable smooth energy transitions during dynamic operation,“ explains Andreas Solheim. „Overall, this leads to noticeably lower operating costs and emissions.“

Reliability and active partnership

NES has been relying on controller solutions from Bachmann electronic for over ten years to meet the high safety and availability requirements. They also form the backbone of energy management in the Windkeeper: No fewer than 33 control systems from the M200 series are installed on board. „We not only appreciate the openness of the system, but above all the exceptional options for grid monitoring and protection,“ explains Andreas Solheim. The grid measurement and protection systems of the GMP and GSP series integrated directly on the control unit are unique on the market: „You won't find any other components with comparable performance and certification.“

Unique network modules

The GMP232/x2 enables the safe, reliable and fast measurement of all relevant parameters of electrical three-phase grids. In addition, numerous monitoring functions are available for the protection of generator units and the grid.

The GSP274 module enables safe, reliable and automated synchronization of generator units to the power supply grid. Furthermore, several monitoring functions are available for generator and grid protection.

Engineering with backing

The NES team worked on the development of the complex energy system for around a year. Bachmann proved to be a reliable partner, particularly when it came to implementing the control technology requirements. „If we had a question or wanted to implement a special function, we could always rely on the support of the application engineers,“ recalls Solheim. „The collaboration was extremely efficient - short paths, direct answers and an open exchange that allowed us to continuously develop our solution.“