Transforming Condition Monitoring

Structural Health Monitoring focused on the wind turbine tower and foundation

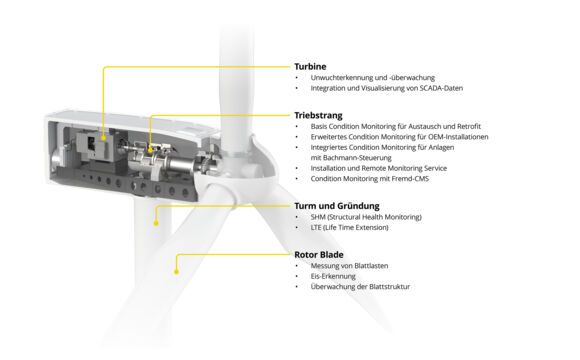

Traditionally, Condition Monitoring Systems for wind turbines concentrated primarily on the drivetrain. Then, given the increase in the number of wind turbines, monitoring the condition of the rotor blades gained more significance. Today, the focus is increasingly on monitoring the tower and foundation by means of Structural Health Management (SHM).

Wind turbines must produce clean energy for 20 years or longer, often under extreme wind and climatic conditions. They must do this reliably and, above all, safely. In Germany, onshore wind turbines are installed in increasingly densely populated areas, even close to built-up areas or roads. If they collapse or parts fall off, human life could be endangered, not to mention the financial loss.

Rotor blade lengths greater than 100 m, total heights greater than 250 m, rated capacities of 12 MW and higher – and the end is not in sight: In the past, wind turbines have increased in size by ten percent every two years. Moreover, new materials and designs are constantly being tested.

The risks associated with construction of a wind turbine are not new: A rotor blade can break; the tower can collapse. On the other hand, structural loads and the associated dangers are increasing due to growing wind turbine dimensions. Thus, the effects of a catastrophe become much more severe.

Risk – or no risk?

Following the standard, twenty-year service life, the question arises as to the current state the structure. Is there any possibility to extend the operating permit for another five or even ten years? If the answer is yes, this massively improves ROI. An extended period of operation also helps bridge the "expansion gap"; the missing capacity required by energy transition targets. But to extend the operating period, the plant operator requires reliable data concerning, for example, whether or not a wind turbine has experienced its original design loads during operation. This is precisely where Structural Health Monitoring (SHM) comes in.

Generating added value existing units

Modern wind turbines are equipped with systems that monitor drivetrain vibration. This is an established method for avoiding catastrophic failure of rotating components. Increasingly, rotor blades are also monitored. However, it is important to monitor the structure to prevent consequential damage. And since precise knowledge of the structure also provides the basis for possible extension to service life, SHM has become more and more important for plant operators and owners in recent years.

SHM systems record actual measured load data, rather than the site-specific loads, which could only be estimated based on SCADA data. As part of an LTE (Lifetime Extension) assessment, actual load data enables load calculation experts to determine the available remaining service life using more dynamic assumptions than were previously possible.

Among other things, Bachmann subsidiary, Bachmann Monitoring, has specialized in the areas of CMS and SHM. Experts at Bachmann Monitoring have developed special algorithms for data analysis, also applying artificial intelligence. This is based on available wind turbine data from the Condition Monitoring System, for instance, as well as measurement data obtained by special sensors that detect and record structural vibration. Bachmann’s SHM-software "CMSSHM" was designed exactly for this purpose. In addition to recording raw data, the CMSSHM software also makes it possible to further process raw data.

3D-MEMS acceleration sensor

Bachmann know-how is also implemented in the hardware. An important component: The 3D-MEMS (Micro Electronic Mechanical Systems) acceleration sensor is a triaxial accelerometer. The sensor records values in all three dimensions. In Bachmann's Condition Monitoring System, it is an important component for detecting and logging structural vibration. For example, signals can be used to evaluate rotor blade imbalance (mass and aerodynamics), to monitor structural condition, and to analyze tower natural frequency

Cantilever Sensor (CLS)

Last but not least: The Cantilever Sensor. The CLS has been developed to detect loads on both rotor blades and wind tower structures and foundations.

The sensor unit, consisting of a cantilever clamped-in one side and a proximity sensor on the opposite side, enables the transition of a strain measurement into a simple distance measurement. Thus, cantilever sensors measure the strain and generate an output signal that can be compared with the electrical strain gauge. In this regard, the CLS itself is not subjected to any mechanical deformation due to the principle of inductive displacement measurement.

Development of the CLS focused on monitoring critical blade loads. Use of CLS signals for individual blade adjustment enables load-optimized matching between turbine design and operating strategy. This in turn considerably lowers the energy generation costs of modern turbines.

Increased safety at a lower cost

Structural Health Monitoring provides information for evaluating structural integrity. Yet it also helps reduce fatigue loads by avoiding unfavorable operating situations that exert stress on the structure. For example, the kinds of stress that would cause resonance of the actual natural frequency of a tower structure. Thus, SHM not only improves the safety of a wind turbine; it reduces maintenance costs. With reliable data concerning the precise state of a wind turbine, SHM can facilitate an extension of the operating permit beyond the planned operating lifetime. This puts money in the pockets of operators of wind energy plants.