Three reasons

to choose the

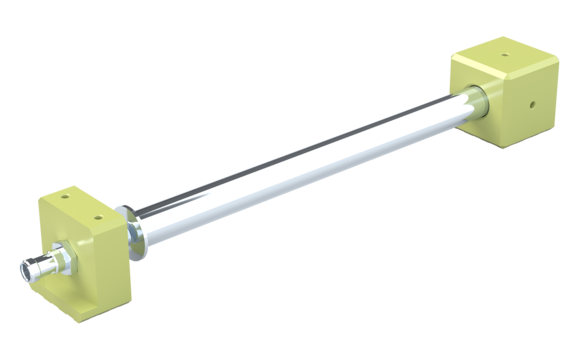

Cantilever Sensor

The cost-effective, high-tech solution for the detection of blade loads for reliable IPC (Individual Pitch Control) system operation.

The Cantilever Sensor (CLS) from Bachmann is a low investment that delivers measurable cost savings over the product lifecycle compared with similar products on the market.

Bachmann in-house production guarantees product quality, as well as reliable delivery, installation support, commissioning and ongoing data acquisition.

The CLS boasts a wide range of additional applications beyond load detection in the rotor blade, an example being structural monitoring of the tower and foundations, which is relevant for Lifetime Extension.

During development of the CLS, the focus was on monitoring critical blade loads. Using CLS signals for individual blade pitch control enables the optimal alignment of turbine design and operating strategy, significantly reducing the power generation costs of modern turbines.

The CLS thus enables the specific adaptation of pitch control strategies, either maximizing performance or extending service life, which generates significant further savings.

Reason 1: Lower sensor and system costs

- Simple and robust sensor technology.

- Avoid complex, specialized sensors and sensitive, high-priced optical-electrical converters.

- No need for additional sensors and subsystems: The blade load sensors can also be used to detect structural anomalies as part of Structural Health Monitoring.

Reason 2: Lower installation, commissioning and quality costs

- Simple, quick and error-free installation and commissioning procedures for assembly, as well as indoor and field commissioning.

- Avoid sensitive fiber optic sensor technology. This means: No expensive test equipment.

- Reliable load signals get Individual Pitch Control (IPC) up and runnning immediately after commissioning, avoiding power loss and delays during the commissioning process, as well as future operator claims for lost yield.