Life Time Extension (LTE)

Too Young to Die

A large number of Europe’s onshore wind turbines are more than 15 years old. With a design lifetime period of 20 years as standard, operating licenses will start to expire over the coming years. Will these turbines need to be decommissioned? Or is there potential to continue operations? These are the questions operators are asking themselves. Bachmann has the answers.

Economic life extension?

When the original service life (as specified in the type certificate) is reached, the operating license of a turbine expires. What should we do? Dismantle the turbine without a replacement, or erect a new one, ideally with a higher output? The buzzword here is repowering. However, regulatory requirements often make this very difficult, if not impossible. In addition, resource bottlenecks and long lead times also come into play.

This raises the question of whether a Life Time Extension (LTE) is possible, and what conditions allow the safe and economical continued operation of the WTG.

Surveyance for extended operation

Any extension of the operational lifetime of a plant beyond the originally prescribed design life requires a continued operations permit. The required ‘Assessment and Verification of the Lifetime Extension’ (BPW) report is carried out by accredited experts and consists of two parts: The practical part, which corresponds to the familiar ‘Recurring Inspection’ (RI) already carried out regularly during operations.

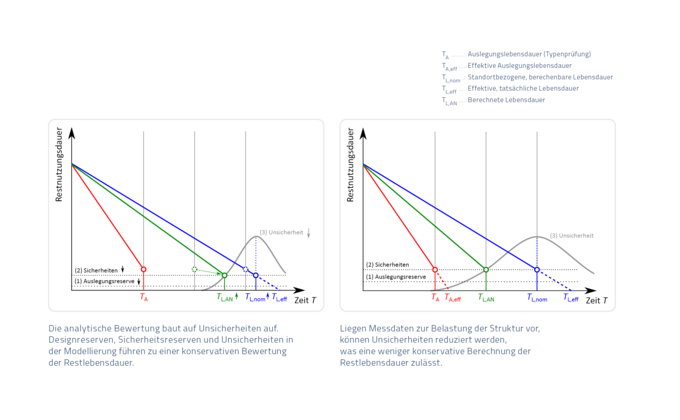

The second, analytical part deals with stability related structures and components that age without any visible or measurable signs. We call this fatigue. "Therefore, assessors must account for fatigue mathematically by determining load cycles experienced by the material and using them to calculate fatigue state. However, load measurement data is often unavailable, in which case load calculation is based on (often incomplete) operating data from SCADA systems, resulting in conservative assumptions about the fatigue state of the plant," explains Marc Thomsen, Product Manager at Bachmann Monitoring.

Although this conservative approach extends the lifetime of the turbine, provided certain requirements are fulfilled, residual life potential often remains unutilized.

Quantifying loads

External conditions are calculated according to statistical values derived from existing plant operating data and various other sources. These include, for example, wind direction and frequency information, as well as the intensity of turbulence. "This also means that such an assessment must be individually calculated for each turbine," says Matthias Saathoff. "Turbulence, in particular, has a major impact on structural fatigue. And here, even within a park, there are very large load differences between individual turbines due to the impact of neighboring turbines." In addition to these parameters, the frequency of critical operating conditions is also evaluated and considered when calculating fatigue loads.

"Because the standard BPW can only estimate site-specific loads based on relatively crude model assumptions about wind conditions and operations, there are inevitably large uncertainties that must be accounted for with high safety factors," says the expert.

Reduce uncertainties

The next goal is to reduce these uncertainties, and the required safety factors, by means of a measurement-based approach that makes optimum use of existing design reserves. "Basically, you can only improve accuracy, and thereby safety, if you have the most precise knowledge possible of actual plant conditions," explains Marc Thomsen. "In this context, the acquisition of load measurement data improves the overall input data for determining park-specific loads during the analytical part of lifetime extension testing."

Anticipate the past

The more measurement data we have about the history of a plant, the more we know about the loads it has experienced, and the more precisely we can forecast its continued operation. However, since it is not possible to measure into the past, the experts at Bachmann and P. E. Concept have been looking for solutions with the help of which the evaluation model used by Saathoff for structural evaluation can be 'calibrated' with current data.

"Of course, measurement data collected towards the end of the service life doesn’t represent the entire history," says Thomsen. But the longer you measure, the less conservative the assumptions become. And the closer you are to reality, the more precisely you can map loads to which the turbine was really subjected. "At this point, we just have to live with compromises," says Thomsen. Even if measurement data is only collected temporarily, perhaps over six months, while you can't completely reproduce or reconstruct the past, it's definitely an improvement on relying solely on SCADA data and theoretical wind models.

Durable sensor technology

Bachmann measurement technology is not only easy and inexpensive to install; it is also extremely stable over the long term. Potential aging won’t influence measurement results because the adhesive connections and the sensor element itself do not have any impact on the forces at work on the turbine.

Properly prepared data

The Bachmann SHM toolbox is an extensive one. In addition to the measurement modules for data acquisition, companies like P. E. Concepts appreciate Bachmann’s expertise in data preparation: "We get exactly what we need," Mathias Saathoff is pleased to say, adding: "We don't have to dig through a mound of measurement data, we get it from Bachmann in exactly the right format to feed into our load calculations relatively easily."

Life Time Extension

Continuing to operate wind turbines beyond their intended end of life not only keeps up the pace of the energy transition in times of resource scarcity; it also reduces waste from decommissioning and preserves the local economic benefits of existing plants.

Plant surveyance is therefore extremely important. The more precise the information on which experts can base their analyses, the easier and more reliably they can identify potential remaining service life.

"Overall, we deliver a lean, low-cost solution that is particularly suitable for older and smaller plants." says Marc Thomsen. "It can be installed with minimum effort, during the course of a practical lifetime extension assessment, for example. And it simultaneously improves safety throughout the period of extended lifetime.”

Contribution

Marc Thomsen

Product Manager, Bachmann Monitoring GmbH

Matthias Saathoff

Team Lead Loads & Life Time Extension, P.E. Concepts GmbH