Key Elements of

Energy Management

Microgrids and energy management

Microgrid and Energy Management

Open. Modular. Secure.

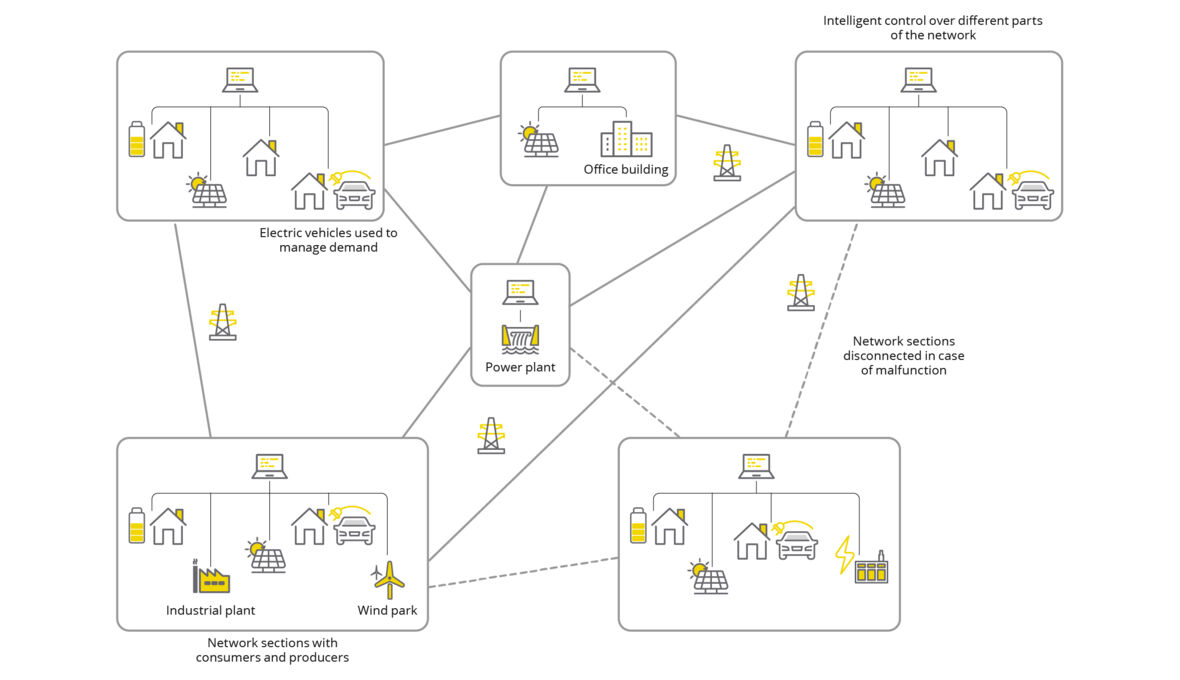

Microgrids are autonomous, intelligent power grids with the capability to operate independently of the public network. A microgrid essentially acts as a decentralized energy system that both connects to and disconnects from the main grid.

A microgrid consists of energy consumers, energy producers, and often energy storage units. Smart components are used to ensure energy balance and voltage stability. Microgrids are not limited by size – any self-sufficient power system can function as a microgrid.

Our Role in your Microgrid

With over 50 years’ experience in automation technology, Bachmann is the ideal partner for your independent energy ecosystem. Our controller technology provides the backbone for seamless operation, while our energy management modules deliver grid measurement, regulation and control powerfully and safely.

Which functional microgrid components do we provide?

The following products should be understood as a multitool for successful and secure microgrid energy management:

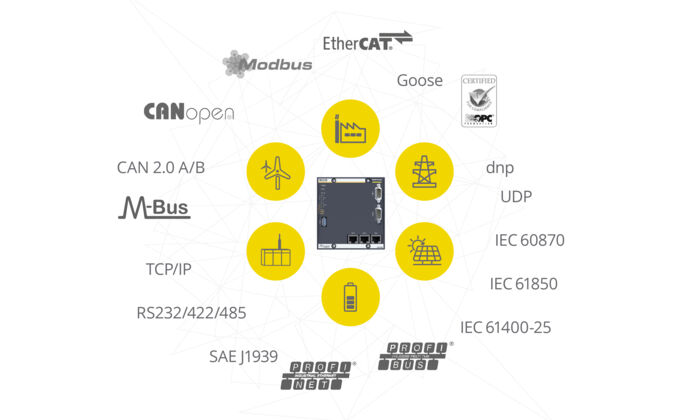

- Open interfaces – fieldbuses and protocols

- Solutions for energy supply – energy management

- Smart power plant controller – EZA controller, compliant with connection guideline VDE-AR-N 4110 for supply

- Application development in all languages – application development in all languages

- World of visualization – one software for all applications

- Security integrated in the control system – multi-level IT security concept

They provide flexible solution modules for a wide range of tasks within a heterogeneous microgrid. For the right mix and the best tool configuration, our expert team is at your disposal – please don’t hesitate to contact us.

Solutions for Energy Supply – Energy management

The widespread use of electricity in all aspects of work and life offers a multitude of benefits, greater convenience and an improved quality of life. In order to ensure energy-optimized solutions in production, buildings and in infrastructures, there is a growing need for these to be based on suitable measuring systems. At the same time, the maintenance of supply security requires integrated solutions for operating grids and the standards compliant management of generating units. Bachmann offers both synergies through the direct integration in the PLC world as well as certified compliance with the latest regulations.

| Application areas | GM260 | GMP232/x | GSP274 |

| Operational measurement | |||

| Energy monitoring | |||

| Power quality | – | ||

| Monitoring/grid connection | – | ||

| Protection function | – | ||

| Online fault diagnostics | – | ||

| Generator connection (synchronization) | – | – |

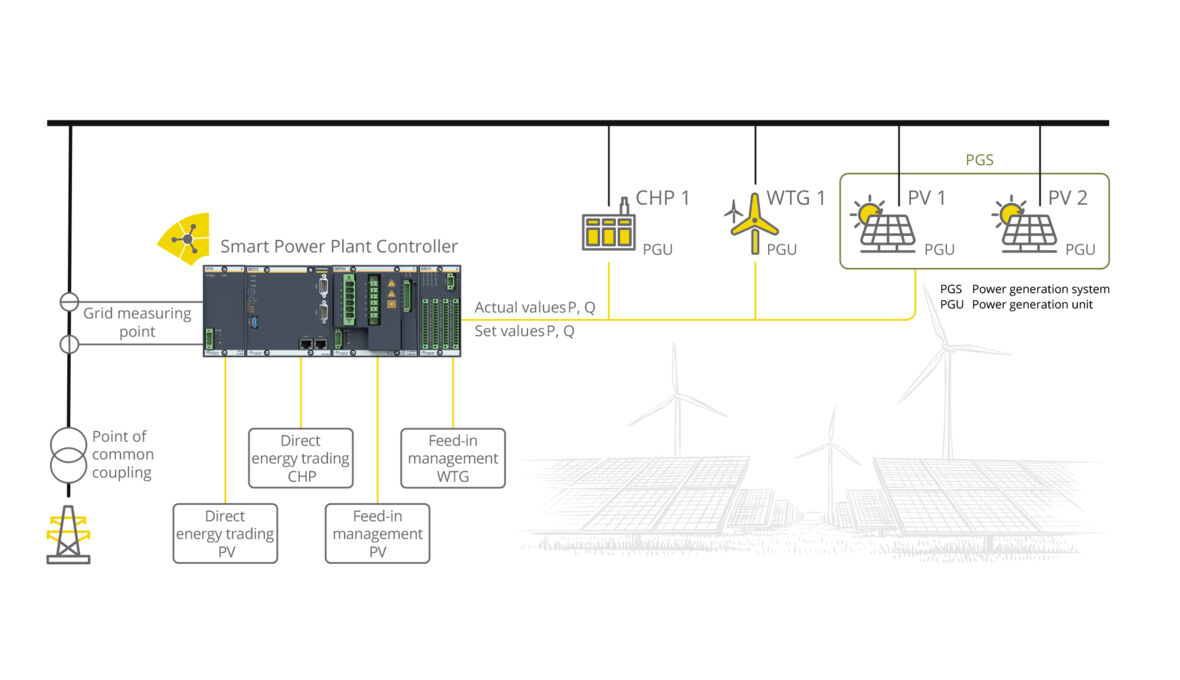

Smart Power Plant Controller (SPPC)

Our clever all-in-one solution.

Application Development in all Languages – IEC 61131-3, C/C++ or MATLAB®/Simulink

Programming is an essential part of the engineering process. Any possibilities to save time in this development step in particular are therefore desirable. The combination of optimum technology for the particular task and helpful functions increases efficiency and improves code quality.

Model-based development with graphical simulation and programming environments are becoming increasingly established tools for complex tasks. These reduce complexity and ensure that the focus is on what is essential: optimum task implementation.

Equipped for the future

The SolutionCenter and the Bachmann controller support a wide range of programming languages: C/C++, all IEC 61131-3 languages and MATLAB®/Simulink. Programmers thus have the possibility to create applications in their familiar environment and language. Existing and established software code can also be reused without any problem. Libraries for PLCs can be created in all languages. The supported languages can also be combined as required.

World of Visualization – One software for all applications

M1 webMI pro

Native web technology used: M1 webMI pro makes it possible to use the advantages of web technologies entirely without restrictive add-ons such as browser plug-ins. All visualization devices from smartphones to powerful operator terminals can be connected, operated and monitored via a web server integrated directly on the Bachmann controller. Wherever and whenever the process requires it.

atvise® hmi

With the atvise® builder as an engineering tool with full graphic support, atvise® hmi offers everything needed for the rapid implementation of visualisations. In addition to an extensive object catalogue, drag & drop support and consistent object orientation, atvise® hmi users also have a fully integrated responsive design framework at their disposal. Numerous prepared dynamizations, drag-&-drop support and high degrees of freedom in implementation enable both beginners and experts to use the atvise® hmi optimally.

atvise® scada

Bachmann’s SCADA system offers a convenient and comprehensive system solution for web-based visualization projects. Maximum flexibility and openness ensure rapid implementation, good maintainability and the possibility to expand the installation efficiently. For example, the process values can be depicted fully according to the IEC 61400-25 interface. This not only simplifies internal communication but also provides external operators and energy companies with uniform access to the specific characteristic values.

Security Integrated in the Control system – Multi-level IT security concept

A selective security management system not only helps with unwanted and potentially destructive hacker attacks. Particularly in the protected environment of production plants, any accidental modification of machine parameters or configuration errors in the machine network are difficult to fully exclude. The effect of these, however, is often as serious as outside threats.

Security as standard: Bachmann protects plants from production failure caused by unauthorized manipulation with a 5-level security concept. The entire Bachmann CPU product range comes with all security functions as standard. This therefore provides the user with an optimized ready-to-use security package.

I would like to know more about the Key Elements of

Energy Management!