Retrofit – Your Wind Turbine, Our Mission

Reliability from the beginning to the end.

WE UPGRADE AND CONVERT EXISTING SYSTEMS TO INCREASE YIELDS.

Longer lifetime + more energy

+ lower costs = optimized earnings

A successful retrofit impresses with the perfect selection of adaptable hardware and software, the right service package and useful options such as an optimum CMS extension. This individually sophisticated interplay of components guarantees permanently profitable system operation.

Increased performance in the long term

Regardless of whether you want to increase yields through optimized operation or gain comprehensive access to machine and system data - the decisive factor is that you win in all disciplines and create added value.

Simple selection from small to large – you decide

The scope of our retrofit package depends on your specifications. From the addition of individual performanceenhancing components to a complete overhaul. Implementing the appropriate retrofit system solution is easy and requires only a few days of downtime.

Retrofit – Process for Maximum Output

We deliver what keeps your wind turbine in the profit zone

When retrofitting a wind turbine, outdated technical components are replaced with new ones to ensure that the turbine continues to operate profitably. We deliver the perfect customized solutions for your plant. Retrofitting with Bachmann means benefiting from the world‘s leading expert in wind turbine automation – at unbeatable prices.

Our quality portfolio includes the optimization of individual components, expansion with special functions through to the integration of CMS solutions – or you can simply choose the complete all-round carefree package. We advise and supply everything from a single source – reliably and with a guarantee.

We are ready for your type of wind turbine

Successful implementations – the basis for your retrofit

We have already given new life to many types of wind turbines. Some examples and their history can be found on this page. With each new turbine type, we enrich our extensive and in-depth knowledge of the perfect retrofit solution for your system. We now have experience from hundreds of installations.

RETROFIT – Across all areas

Retrofit with extras

You want to get more out of it? Yes – but always with added value, please.

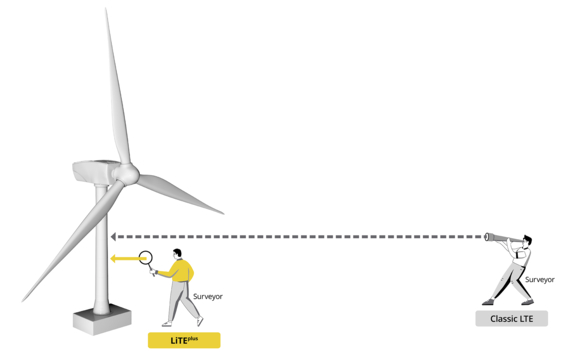

LiTEplus for wind turbines

Extend the life of your wind turbines well beyond the design service lifetime.

Many wind turbines still have considerable lifetime reserves even after the original design lifetime, typically 20 years, has expired. With Lifetime Extension (LTE), wind turbines with demonstrable residual lifetime can remain in operation, sometimes for many additional years. When a wind turbine reaches the end of its estimated lifetime, owners and operators can order an LTE Assessment to demonstrate that their turbines are still in good condition. This is the approval channel for continuing operations beyond the design lifetime.

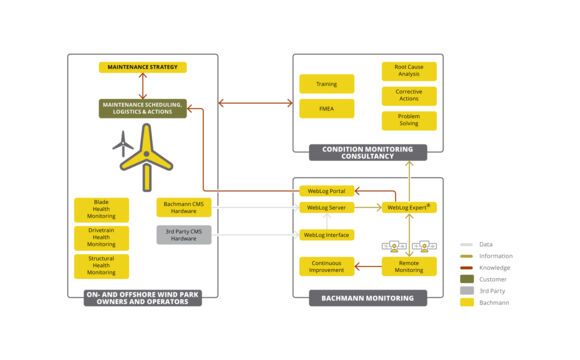

CMS – always worth it

Condition monitoring systems from Bachmann not only provide operational and maintenance reliability, but also keep you informed about the health status of your systems at all times. Depending on the application and operator requirements, we supply everything from Quick&Easy to WOW&Fantastic. However, we only ever recommend what your system really needs.

CMScore

Game Changer: With our CMScore, we are opening up the lower price sector for professional condition monitoring systems. At the same time, we remain fully committed to our quality standards, which makes CMScore a game changer for our customers in particular. The basis of reliable monitoring is the high-quality acquisition of sensor signals.

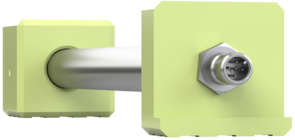

Cantilever Sensor (CLS) – Inspiring sensor technology

The sensor solution offers easy installation and minimal system costs. Its high long-term stability reduces replacement and down-time costs. The robust design withstands environmental influences, while the versatile applicability enables blade load detection and structural analysis. Thanks to excellent signal quality, the sensor helps to reduce the levelized cost of energy (LCoE).

forsiteSCADA – always worth it

Together with our retrofit solutions for control, Bachmann offers the perfect visualization product with forsiteSCADA. Perfectly matched to all Bachmann hardware components, the range of functions is far superior to other systems. There is no need for lengthy system setup; the configuration of the SCADA system is created automatically and the system is ready for use with the individual data set in accordance with IEC 61400-25. The visualization is browser-based, multi-client capable and highly adaptable to individual requirements.

Modernize your plant controller with SPPC!

Is your current plant controller outdated or no longer supported? Our SPPC (Smart Power Plant Controller) is a certified plant controller that offers easy commissioning and an integrated, browser-based visualization. Depending on the brand and setup, it can connect directly to the turbines or the existing plant controller.

SPPC is also ideal for hybrid plants and enables the control of PV/solar systems, other energy generation units and battery storage. At the same time, it meets the latest safety and TSO requirements.

Your package – your success

And quality for a long time into the future

Many skills are required from the first meeting to successful implementation. It is a sign of quality when customers keep coming back because they appreciate the consistent focus on solutions as well as the respectful cooperation. Our employees‘ many years of experience create security and trust.

Quality for the future

- Quality and durability – the hallmarks of all Bachmann products

- Distinctive quality of detail in parts and components

- Compliance with the highest environmental standards throughout the entire production chain

- State-of-the-art manufacturing and testing processes

- 48-hour climate stress test for each hardware module

- ISO 14001 certified

The right solution is a matter of trust, which is why we always offer a no-obligation consultation with our experts. It is important to us that you feel confident about your choice of system solution and the right partner.