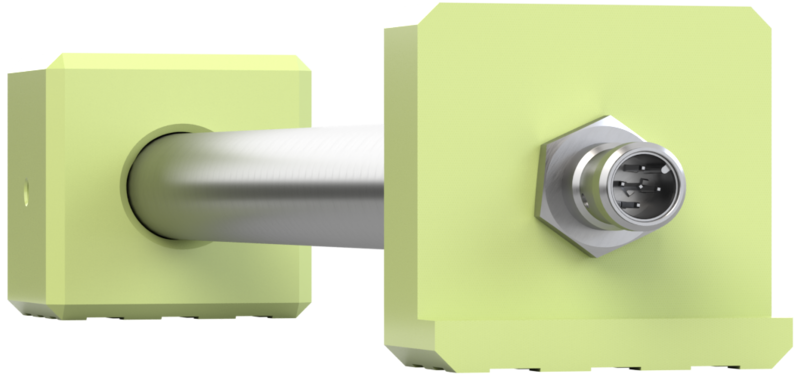

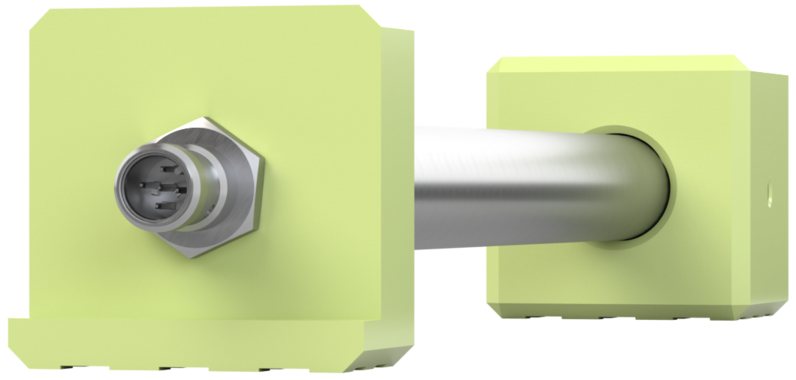

Cantilever-Sensor (CLS)

Sensor for structural loads

The Cantilever-Sensor was designed for the continuous load recording on the rotor blades as well as on tower and foundation structures of wind turbines.

The sensor unit, consisting of a cantilever fixed on one side and an opposing proximity sensor, makes it possible to convert a strain measurement into a simple distance measurement. This way, cantilever sensors measure strain, producing a value comparable to the output from electrical strain gauges or fibre-optic strain sensors. However, by using an inductive displacement measurement the CLS itself is not subject to mechanical deformation.

Compared to conventional sensor technologies, the robust design of the CLS offers the following advantages:

- The measurement principle guarantees the long-term stability of the sensor.

- The longer reference distance minimizes the influence of local inhomogeneities, typical of composite materials used for blade construction.

- Simple installation suitable for series production by bonding the sensor unit pre-aligned to a mounting rail.

The CLS has a wide range of applications:

- The signal provides real time blade loading information suitable for individual pitch control.

- Comparison between the different blade loadings on a single wind turbine can identify problems such as pitch errors or individual blade damage.

- The response time and sensitivity enable sampling rates sufficient to capture structural oscillations of the blade, for ice detection, and structural integrity studies.

- Continuous recording of the signal allows a facility-specific estimation of the remaining service life of structural components

The monitoring of critical blade loads was the main focus for developing the CLS. The use of CLS signals for individual pitch control allows coordination between turbine design and operational strategy in a load-optimized way in order to considerably reduce the levelized cost of energy of modern turbines.

Thus, the CLS enables further specific adjustment of the pitch control strategies, either to maximise output or to extend life, providing further significant savings.