CMSadvanced

Certified monitoring solution

The condition monitoring system CMSadvanced is an intelligent monitoring solution without mechanical moving components such as hard disks or fans, which is robust for use under harsh environmental conditions. The system is tested and certified to DNV requirements.

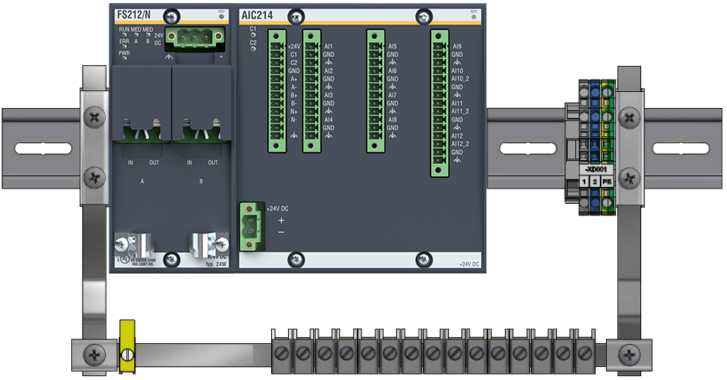

The hardware and software architecture is based on a modular concept, providing flexibility to configure analog and digital inputs and outputs. Different system variants are available, which enable both drive train monitoring and structural monitoring tasks.

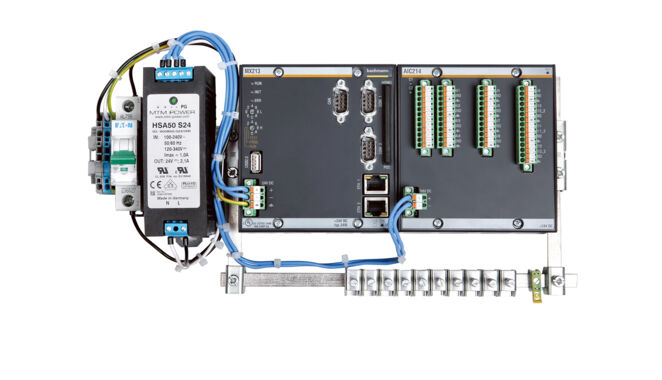

CMSadvanced stand-alone systems are installed in their switch cabinet, enabling flexible installations in the plants to be monitored. CMSadvanced Top Box, on the other hand, is designed for installation in existing switch cabinets. The CMSadvanced integrated solution is designed for systems in which Bachmann main controllers are used. The drive train monitoring is individually integrated into the main controller so that no additional processor module is required.

CMSadvanced offers a range of sample rates with corresponding filters. Vibration signals are processed in accordance with ISO guidelines for machine vibration to provide realtime rms values of acceleration or velocity as a continuous output. System software also captures frequency data periodically for the purposes of condition monitoring.

Bachmann prides itself on the high quality of hardware. Our systems in the field exceed 99.9 % availability. However extensive self-test routines enable a detailed functional check of the CMS including connected sensors.

The Bachmann software offers standard routines for all tasks in connection with vibration monitoring. Plug-ins allow extensions to these functions. Script-oriented software enables easy adaptation of monitoring tasks that can arise due to special requirements for specific system parts.

Features

- Modularity

- Easy to expand

- Supports many data formats (CAN, Profinet, OPC etc.)

- Can be integrated within Bachmann controllers

- Continuous ISO rms values

- Wide operating temperature range

- Robust to environmental influences

- Watchdog self-monitoring

- Wide range of sample rates

- Web-based Weblog software and client-based WebLog Expert software for remote monitoring and diagnostics

- DNV certification

- Support from Bachmann’s DNV certified monitoring team