M100 Control System

Control-Systems for Demanding Applications

For over 55 years, Bachmann electronic has stood for efficient engineering, exceptional performance, and unmatched robustness. The M100 is the next step on our journey.

The market landscape in the coming decades will face challenges unlike any before. Emerging technologies, the demand for greater efficiency and uptime, and the rising importance of data are driving change. The same holds true for control, networking, and automation systems.

With the M100, Bachmann offers a brand-new control platform as the foundation for advanced automation tasks. Powerful CPU modules, advanced security, extreme I/O bandwidth, and real-time networking – all within a future-proof, scalable architecture. The boundaries between measurement technology, industrial control, motion controllers, edge devices and IoT are disappearing.

We stay aligned with the demands of this challenging segment. The priorities remain the same – unmatched robustness, efficiency, and performance.

Uncompromising industrial control technology

36 channels per module

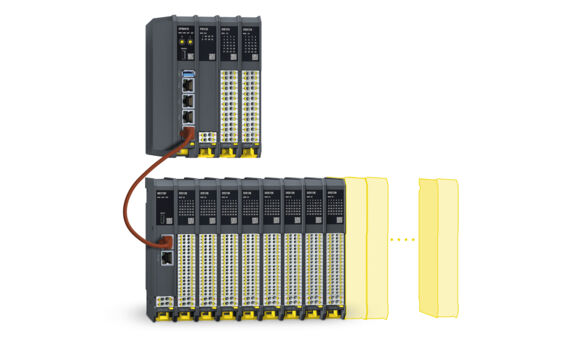

Deformation-free, load-bearing, active backplane

Lag-free module-to-module communication

4 to 32 modules bolted per station

24 mm pitch up to 1080 digital or 496 analog channels

> 16 stations per system (based on the fieldbus technology)

M100 CONTROL SYSTEM PRODUCT GROUPS

Channel-specific function configuration.

Fewer module types, fewer unused channels, greater flexibility.

High functional and performance density in an uncompromisingly robust design

The software makes all the difference

Engineering – turning efficiency into a competitive advantage

The software delivers value on at least two levels: First in the configuration and programming phase, and later during real-time operation. The M100 redefines both: The architecture describes itself, engineering tools are both intuitive and efficient, and interfaces align with the evolving needs of a connected world. What truly remains unchanged is the reliability factor.

System & Engineering

- Development environment: SolutionCenter and configuration in the browser

- Supports programming in IEC 61131-3, C and C++ (Simulink support under development)

- Integrated channel/module/station and heterogeneous fieldbus configuration

- Packet-oriented real-time Linux as the foundation, distributed synchronous clocks

- Automation-specific interprocess communication

- Call synchronization and scheduling, process separation (Apparmor)

- Real-time data recorder with analysis front end, OPC UA server onboard

- Server for web visualization (webMI)