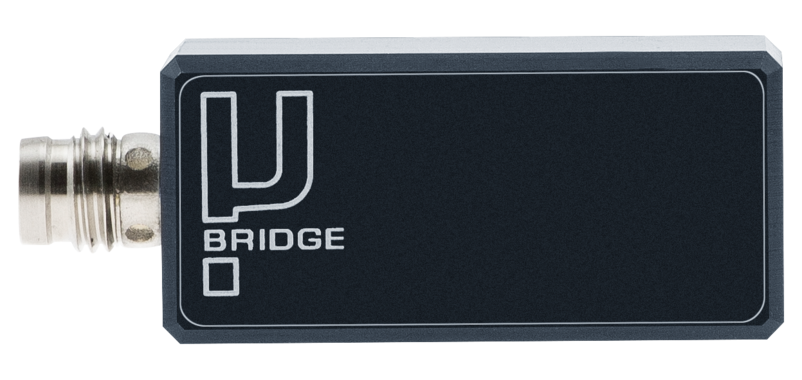

µ-bridge

Sensor for sound waves and flexural vibrations

Impacts and the growth of defects in a material will generate stress waves, which travel at the speed of sound (in the material) through the machine. For example if a small defect is present in a rolling element bearing, every time an element passes over a defect, a wave will be produced.

There are several methods available to detect these waves. We use a force bridge transducer known as a µ-bridge (my-bridge).

On low speed shafts the impacts due to bearing defects are often in a similar frequency range to the running speed of other components, which generate vibration of the entire machine and are picked up by standard accelerometers, with the result that the small defect signals are drowned out. Stress waves are not normally generated by the rotation of the machine, so stress wave methods are better at detecting defect indications on the low speed components of machines.

Our transducer has two patches which have to be individually attached to the surface of the machine. The transducer then measures the force between these two points using the mechanical bridge as an amplifier to provide sufficient strain to be measurable. Built in electronics provide temperature compensation and convert the signal to an IEPE format.

Features

- Specific to Bachmann

- Uses well established principles

- Detects impacts rather than machine vibration

- Analogous to acoustic emission or shock pulse methods

- Very good performance on very low speed bearings – good track record